About Us

Global Enterprises was founded in 2005 with a mission to deliver premium Aluminium products to industries across India. Over the years, we established ourselves as a reliable supplier of aluminum dross, powder, and secondary ingots.

Recognizing the evolving needs of the foundry and steel industries, we ventured into manufacturing in 2020, introducing innovative solutions such as exothermic sleeves, insulating sleeves, hot tops, and APC powder.

We are proud to be a customer-focused company, offering customized sizes and shapes for our products to suit specific requirements. With a legacy of excellence, we aim to remain your trusted partner for foundry and steel solutions.

We are proud to be a customer-focused company, offering customized sizes and shapes for our products to suit specific requirements. With a legacy of excellence, we aim to remain your trusted partner for Ferrous and Non-Ferrous Foundry Metal Solutions.

-

Our Vision

To lead the industry with innovative, sustainable, and high-quality solutions that improve efficiency and enhance metal yield.

01 -

Our Mission

Deliver excellence through precision manufacturing, unmatched customer support, and bespoke solutions tailored to our clients’ needs.

02 -

Our Facility

- Our manufacturing plant, located in the scenic Wada Taluka of Palghar District near Mumbai, is the backbone of our operations.Spread across a vast 20,000 sq. ft., our facility is the epitome of innovation and quality, featuring state-of-the-art testing laboratories that form the backbone of our commitment to precision and consistency. These advanced laboratories are meticulously designed to ensure that every product not only meets but exceeds quality benchmarks. What truly sets us apart is our ability to deliver customized solutions, leveraging this sophisticated infrastructure to cater to the unique needs of our clients with unparalleled accuracy and excellence.

- One of our key strengths is our in-house tooling and customization capabilities, allowing us to develop unique sizes and shapes for our products based on customer requirements. With a dedicated focus on quality and innovation, we aim to exceed industry standards and set new benchmarks in manufacturing excellence.

03 -

Our Commitment to Quality

We are committed to delivering products that not only meet but exceed our customers’ expectations. To achieve this, we adhere to stringent quality control measures throughout the production process, from the selection of raw materials to the final inspection and testing. Our team of skilled professionals ensures that each product is thoroughly tested for durability, efficiency, and compliance with industry regulations. We believe in fostering long-term relationships with our customers, and our consistent focus on quality and service is a testament to our dedication.

04

Products

At Global Enterprises, we take pride in offering a diverse range of high-performance products tailored to meet the dynamic requirements of foundries and steel plants. Each product is designed with precision engineering and manufactured to ensure exceptional efficiency, quality, and reliability. Let’s take an in-depth look at our product offerings:

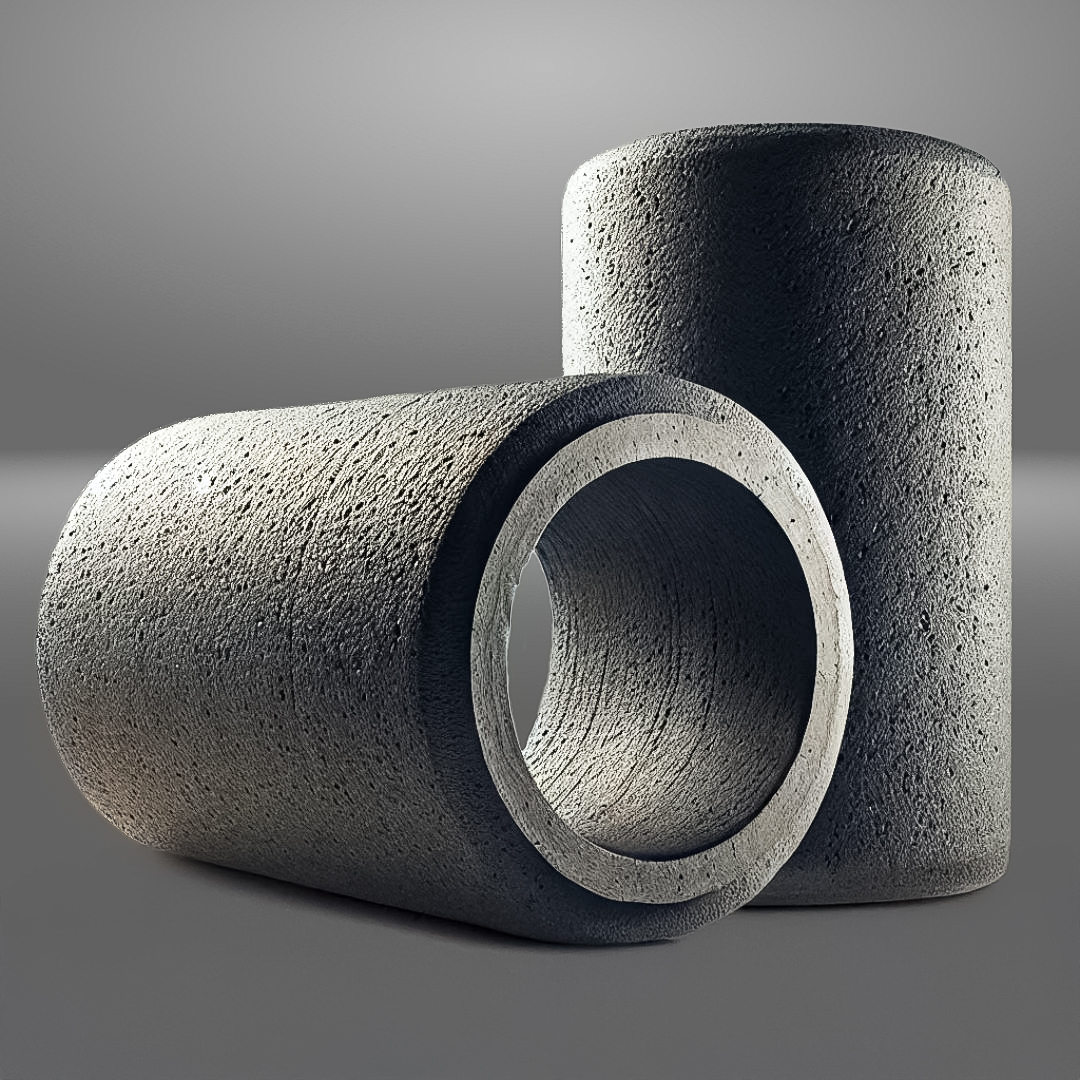

Exothermic Sleeves

Exothermic sleeves are a critical component in the casting process, designed to optimize metal yield and minimize wastage in foundries. These sleeves generate heat during the solidification of molten metal, keeping the metal in a liquid state for a longer duration and reducing shrinkage defects.

Key Features:

- Manufactured using high-grade materials for superior heat generation.

- Designed to improve the directional solidification of metal, reducing porosity and ensuring high-quality castings.

- Available in a wide range of shapes, including:

- Globex Open Sleeves

- Globex Blind Sleeves

- Globex Elliptical Sleeves (Oval sleeves)

- Globex Neck Down Sleeves (ND)

- Globex Foot risers (Bottom risers)

Applications:

- Widely used in steel and foundry industries to increase metal recovery and enhance casting accuracy.

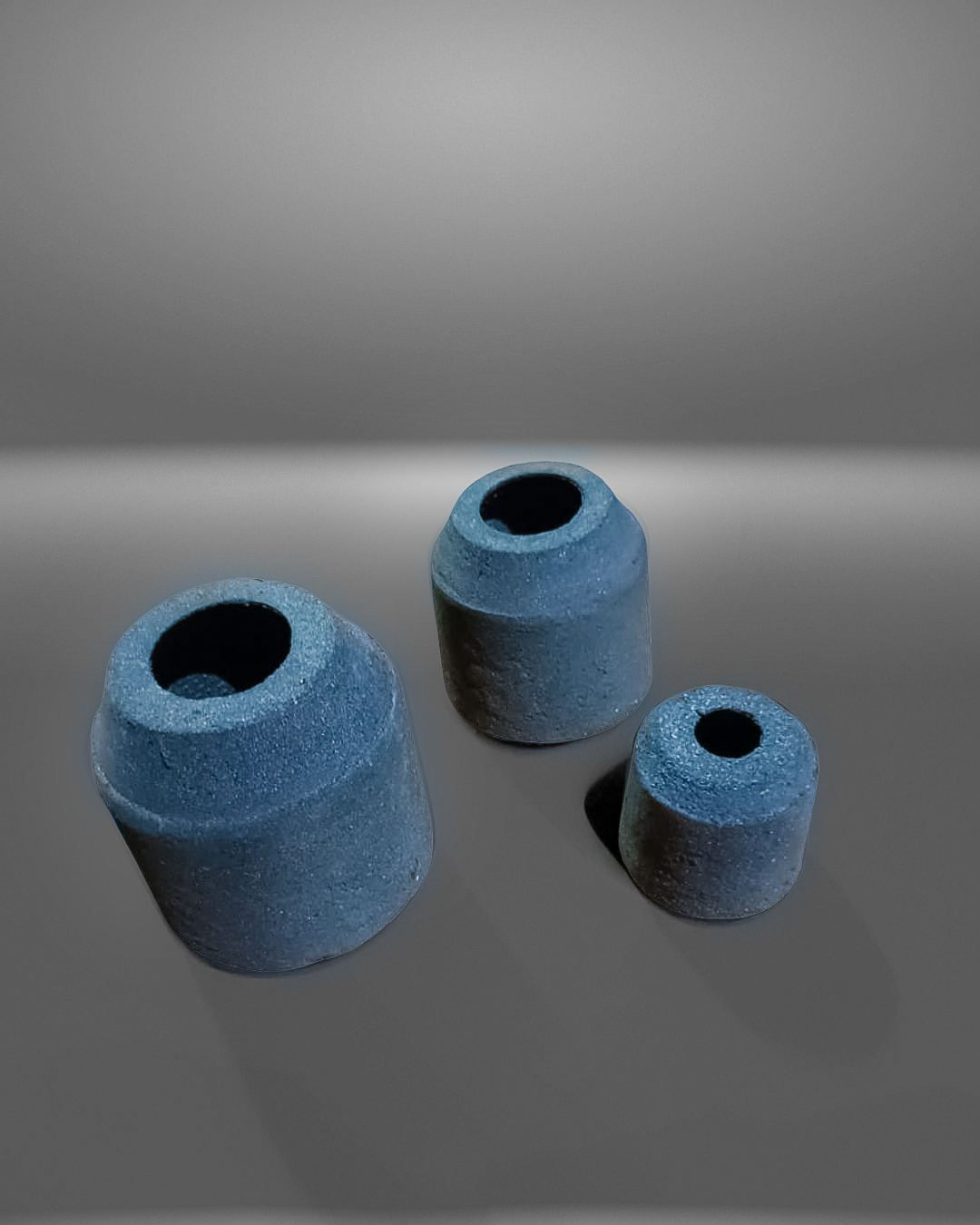

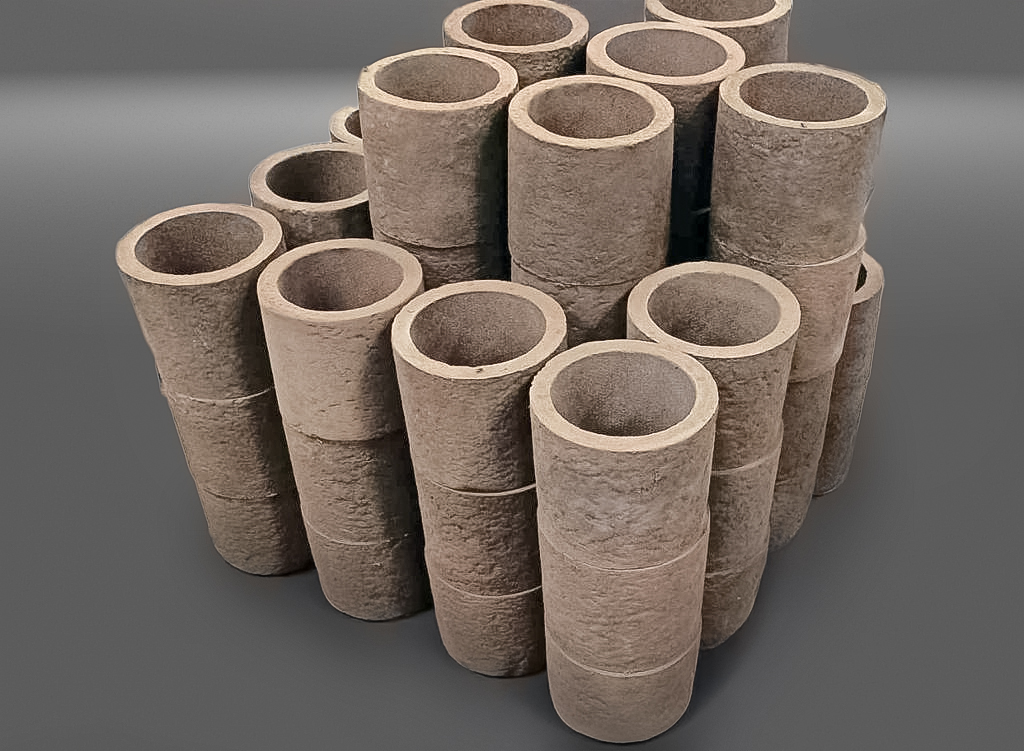

Insulating Sleeves

Insulating sleeves are designed to retain heat during the casting process, ensuring that the molten metal cools at a controlled rate. These sleeves do not generate heat but act as an insulator to maintain the temperature of the metal for longer periods.

Key Features:

- Lightweight and made from thermally efficient insulating materials.

- Ensures a consistent solidification process, leading to better structural integrity of castings.

- Reduces energy consumption by minimizing the need for reheating processes.

- Available in wide range of shapes and sizes, including:

- Globin Open sleeves

- Globin Neck Down sleeves (ND)

- Globin elliptical (Oval sleeves)

Applications:

- Suitable for castings that require precise solidification control, such as automotive and aerospace components.

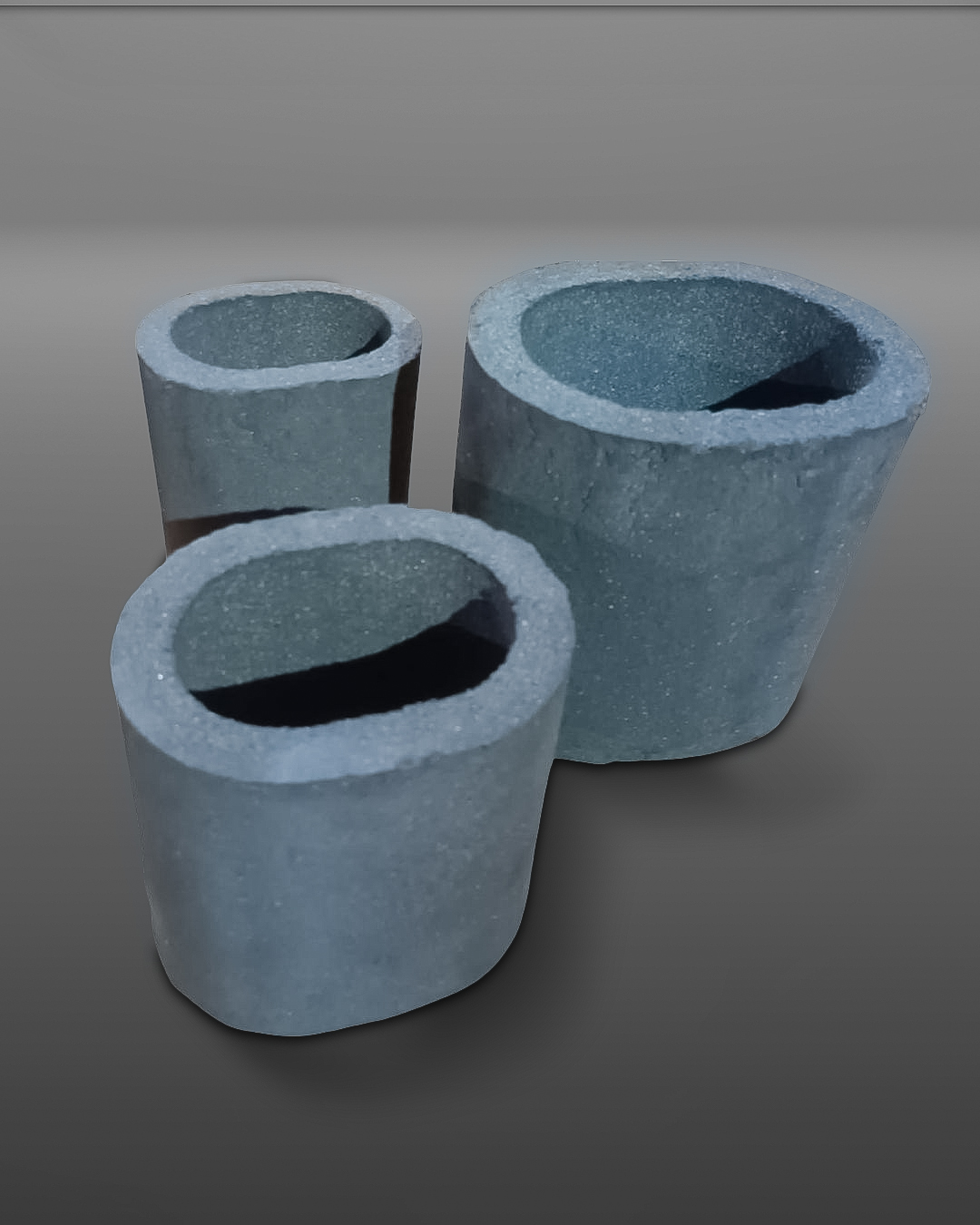

GLOBEX Hot Tops

Hot tops are specialized products designed for steel plants to manage the solidification of molten metal during the casting process. These components play a pivotal role in improving casting efficiency and minimizing defects.

Key Features:

- Helps control the solidification process by retaining heat at the top of the mold.

- Reduces wastage of molten metal by improving directional solidification.

- Enhances the yield and surface quality of castings.

Applications:

- Primarily used in steel plants and heavy casting operations requiring high-quality outputs.

Customized Solutions

At Global Enterprises, we understand that every customer’s requirements are unique. To cater to these specific needs, we offer fully customized solutions. At the heart of this capability is our in-house tooling workshop, which empowers us to design and develop products in a wide range of sizes, shapes, and specifications. This advanced facility ensures precision, flexibility, and speed in delivering tailored solutions that perfectly align with our customers' expectations.

Capabilities:

- Custom molds and tools for specialized sleeve shapes and dimensions.

- Prototype development and testing to meet client specifications.

- Flexibility to manufacture sleeves with unique properties tailored for specific casting applications.

Benefits:

- Improved compatibility with specific casting setups.

- Optimized performance tailored to individual operational requirements.

- Faster turnaround times due to our in-house design and manufacturing capabilities.

Optimized for Your Needs

Our sleeves are specifically designed to cater to various industrial sectors, providing you with:

- Flexibility: Multiple size options to fit diverse applications.

- Quality Assurance: Built to withstand demanding conditions.

- Efficient Solutions: Packaging designed to optimise storage and reduce costs.

Whether you need Open Sleeves, Neck-Down Sleeves, or custom-sized solutions, Global Enterprises is committed to delivering the best in quality and performance. Explore our wide range of products today and find the ideal sleeve for your business needs. For further details or to place an order, please contact us now. Our team is ready to assist you in selecting the right solution.

Open Sleeves

Open Sleeves

Open Sleeves

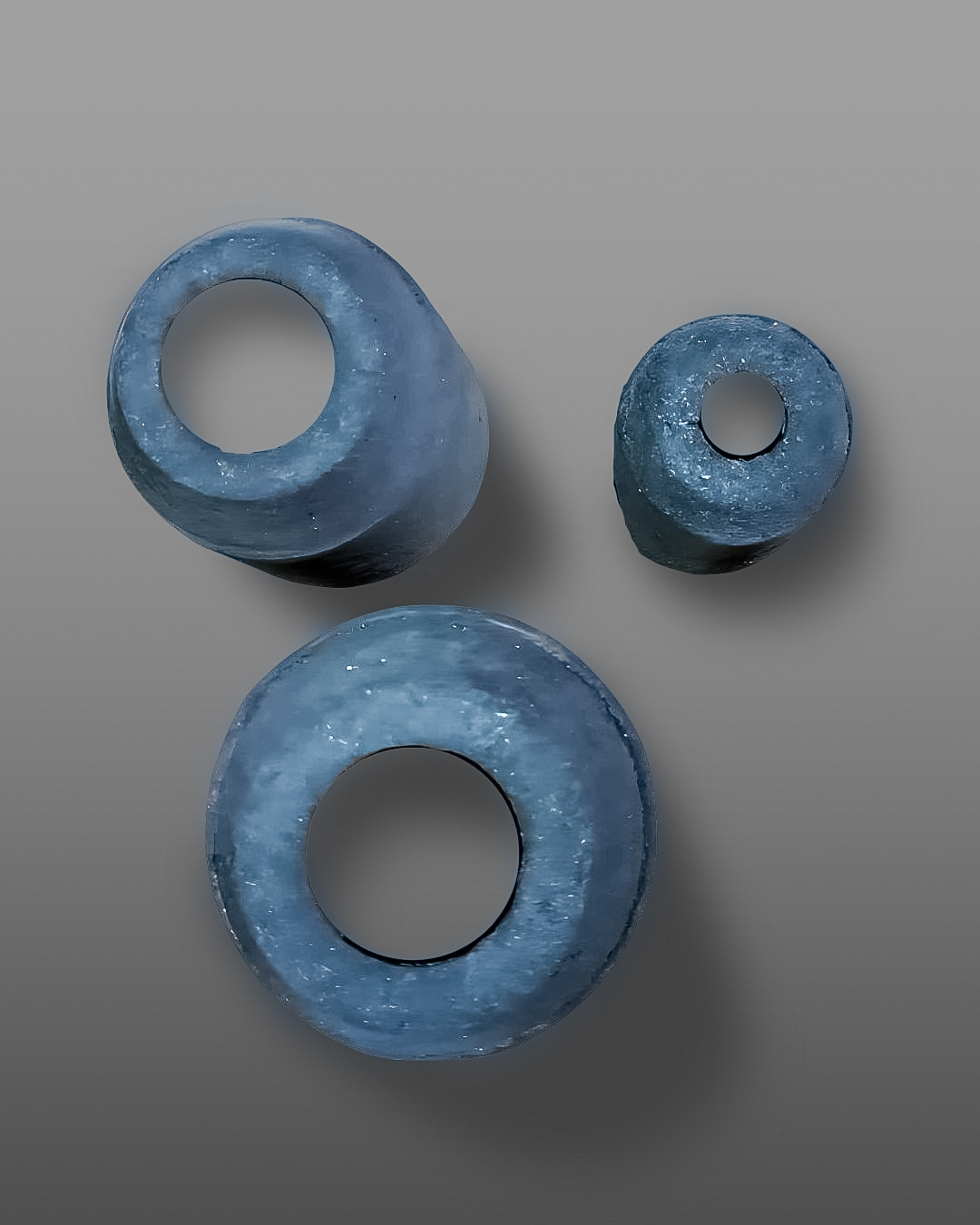

Blind Sleeves

Neck Down Sleeves

Neck Down Sleeves

Neck Down Sleeves

Neck Down Sleeves

Foot Riser

Foot Riser

Oval Sleeves

Globex Hot Tops

Globex Hot Tops

Globin Open Sleeves

Foundries

Providing solutions that enhance metal yield and efficiency

Steel Casting Plants

Offering products like exothermic sleeves and hot tops for optimal solidification.

Automotive Manufacturers

Delivering high-quality solutions for precision casting requirements.

Aerospace Components

Supplying products that meet stringent quality standards.

Our Brand Promise

At Global Enterprises, we are driven by a singular goal: to deliver innovative, sustainable, and high-quality solutions that empower foundries and steel plants to achieve superior results. With precision engineering, advanced facilities, and a customer-first approach, we are redefining excellence in the foundry and steel industry.

Get in touch with us

-

Contact Us

We are here to assist you with your foundry and steel plant needs. Reach out to us via the following channels

- Email:

● General Inquiries: info@globalen.in

● Sales: sales@globalen.in

● shafi20968@yahoo.co.in

● Purchase: purchase@globalen.in

- Phone: +91 9821020968

- Address: Gut No. 162/1, 194/5, Village Met & Nare (Tansa Farm), Bhiwandi-Wada Road, Taluka Wada,Palghar-421313, Maharashtra, India.

- Email: